Environmentally Sustainable Glass

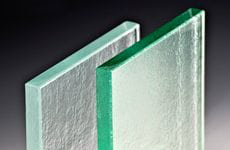

Environmentally Sustainable Glass. Glass is often referred to as a Green product, because the main component to making glass is Silica. Found in sand, Silica is considered a renewable and never ending resource. Kiln cast glass offers decorative textures without compromising the environment. Neither plastics nor resin are used in any of our processes. When you choose to use glass, it’s an everlasting authentic statement Mother Nature can live with.

Our Process

In the process of making float glass sheets, excess or marked portions of the glass are cut off and re-used in future production runs. Percentages will vary as to how much content of the glass is recyclable product. Stock glass is shipped to Nathan Allan, and we use this glass to manufacture all of our products. Currently, the glass sheets that Nathan Allan uses to produce our Cast Glass contain up to 30% recycled cullet. Once glass is tempered, it cannot be cut. If someone attempts to cut tempered glass, the glass will explode. We focus on Environmentally Sustainable Glass. Companies will often discard tempered glass when panels are scratched, damaged, or ordered incorrectly.

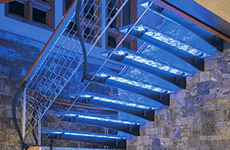

Nathan Allan has eliminated the need to discard glass by using a process in which we formulate and de-temper the tempered glass. After the panels are de-tempered, we can cut, re-cast, and re-use these panels in future projects. This ingenious process has eliminated the exercise of discarding of glass panels. While providing beautiful decor, our Cast Glass also allows for ample light and warmth transmission from the sun, reducing the need for artificial lighting and heat.

Cleaning Properties

Cast Glass has unique cleaning properties. With the surfaces of the glass being textured or sealed, it is essentially a No-Maintenance product. In years to come, the glass looks brand new, reducing the need to replace the glass with newer product. This also helps to eliminate the process of discarding glass into landfills. Nathan Allan is in the process of applying for LEEDS certification. As we upgrade our building, improve manufacturing processes, and continue to increase our recycling capabilities, we look forward to being a partner in maintaining the natural beauty of the world in which we live!

USGBC LEED-CI OPPORTUNITIES IN SPECIFICATION

Designers and Architects are provided this document to assist in the specification of Nathan Allan Glass Studios’ glass to potentially earn LEED-CI credits for their projects. This is an outline only and confirms only LEED credit opportunities. Environmentally Sustainable Glass Specific criteria as per LEED-CI documentation should be directed to USGBC per LEED-CI requirements. View Our YouTube Videos.

LEED credit |

Intent |

Requirement |

Opportunity |

|---|---|---|---|

Energy andAtmosphereOptimizing |

Environmentally Sustainable Glass. To achieve increasing levels of energy conservation beyond the referenced standard to reduce environmental and economic impacts associated with excessive energy use. | Reduce connected lighting power density below that allowed by ANSI/ASHRAE/IESNA Standard 90.1-2007 (with errata but without addenda) using either the space-byspace method or by applying the whole building lighting power allowance to the entire tenant space. | Nathan Allan Glass Studios’ glass specified in facility design can reduce daylight costs of electricity and provide additional natural lighting throughout. The distinct pattern designs of Nathan Allan Glass Studios’ glass therefore reduce thermal solar effects as well. |

Materials andResourcesCredit 4.1-4.2 |

To increase demand for building products that incorporate recycled content materials thereby reducing impacts resulting from extraction and processing of virgin materials. | Use materials with recycled content such that the sum of postconsumer recycled content plus 1/2 of the preconsumer content constitutes at least 10% or 20% based on cost of the total value of the materials in the project. | Nathan Allan Glass Studios has developed a process for de-tempering misused, damaged, or incorrectly produced tempered glass panels, which would typically be discarded in a landfill. Nathan Allan has also developed a process where any misused, damaged, or incorrectly produced Annealed glass panels can also be recycled and reused. By definition, specific glass panels which we produce fall under the LEED section of 7.8.1.1 of ISO 14021:20012, for both pre-consumer and post-consumer material. Some of our glass panels would be considered 100% Pre-Consumer material and others would be considered 100% Post-Consumer material. |

Materials andResourcesCredit 5.1-5.2 |

To increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the regional economy and reducing the environmental impacts resulting from transportation. | Use a minimum of 20% of the combined value of construction materials and products that are manufactured regionally within a radius of 500 miles. Use a minimum of 10% or 20% of the combined value of construction materials and products extracted, harvested or recovered, as well as manufactured, within 500 miles of the project. | Projects within a 500 mile range of Nathan Allan Glass Studios’ Vancouver area production facility may qualify for credit. |

IndoorEnvironmentalQualityCredit 4.1-4.2 |

To reduce the quantity of indoor air contaminants that are odorous, irritating and/or harmful to the comfort and wellbeing of installers and occupants. | VOC content must meet or be less than the current VOC content limits of the South Coast Air Quality Management District (SCAQMD), Rule #1169 Adhesives, Rule #1113 Paints and Coatings. | Nathan Allan Glass Studios’ durable paints meet the most stringent qualifications. They are HAPS (Hazardous Air Pollutants) free and low VOC (Volatile Organic Compounds) at application, Zero VOC upon curing. |

Indoor Environmental

|

To provide occupants with a connection between indoor spaces and the outdoors through the introduction of daylight and views into regularly occupied areas of a tenant space. | Use a combination of side-lighting and/or top-lighting to achieve a total daylight zone that is at least 75% of all the regularly occupied spaces, 95% for additional credit. | The specification of Nathan Allan Glass Studios’ glass offers natural lighting conveyance to all areas to the work environment, while our textures and designs provide privacy along with light transmission. |

IndoorEnvironmentalQualityCredit 8.2-8.3 |

To provide building occupants a connection to the outdoors through the introduction of daylight and views into the regularly occupied areas of tenant space. | Achieve a direct line of sight to the outdoor environment via vision glazing between 30 inches and 90 inches above the finished floor for building occupants in 90% of all regularly occupied areas. | Nathan Allan Glass Studios’ innovative glass textures and designs, strategically placed, provide building occupants improved natural daylight solutions. |

Innovationand DesignProcessCredit 1 |

To provide design teams and projects the opportunity to achieve exceptional performance above the requirements set by the LEED Green Building Rating System and/or innovative performance in Green Building categories not specifically addressed by the LEED Green Building Rating System. | Credit can be achieved through any combination of Innovation in Design and Exemplary Performance paths. | Nathan Allan Glass Studios’ R & D is focused on new one of a kind, green product introductions. Within the next few months Nathan Allan Glass Studios is introducing maximum content pre and post-consumer recycled lines. Nathan Allan Glass Studios is the go to company for innovation, new technology and wonderful green products in kiln-formed glass. Please contact us for additional information about Environmentally Sustainable Glass. |

LEED Certified Projects